Product selection guide

Areas where dusts are generated

Areas where oil or moisture are generated

Areas where odor and gas are generated

Oil Mist Collector

Request for quote/visitRelated link

본문

Feature

■ Features

1. With 3-layer filter, it collects more than 98% of vertical and horizontal particles

(base oil, additives <water-soluble, non-water-soluble>)generated from the machining equipment.

2. With simple and compact structure, it allows easy installation and takes up less space.

As additional facility(i.e.DUST HOOD) can be installed at low cost, air conditioning cost can be reduced. .

3. The mist cleaner can be installed in various forms according to the situations.

(Diverse installation, such as direct installation on the machine, using HOOD, DUCT, branch pipe, etc.)

4. With filter unit method that does not require additional tools, it allows easy replacement.

■ Applications

- Lathe machine (automatic lathe), milling, grinding, boring, hopping drill, food processing, electric discharge processing

* Filter replacement interval is 1 year (based on 10-hour use per day)

Specification

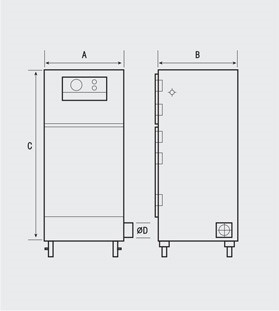

MODEL |

YC-3000 |

YC-5000 |

YC-7500A |

A |

770 |

770 |

1540 |

B |

770 |

770 |

770 |

C |

2120 |

2120 |

2400 |

D |

200 |

250 |

300 |

MODEL |

YC-3000 |

YC-5000 |

YC-7500 |

POWER |

Three phase 220V / 380V 440V (50/60Hz) |

||

Output (Kw) |

2.2 |

3.7 |

5.5 |

Air flow (㎥/min) |

40 |

60 |

60 |

Static pressure(mmAq) |

230 |

230 |

230 |

Weight (kg) |

130 |

180 |

205 |

* The above specification is based on 60Hz. When 50Hz is applied, the air flow volume decreases by about 20%.