精密配件

정밀부품

Related link

Contents

Feature

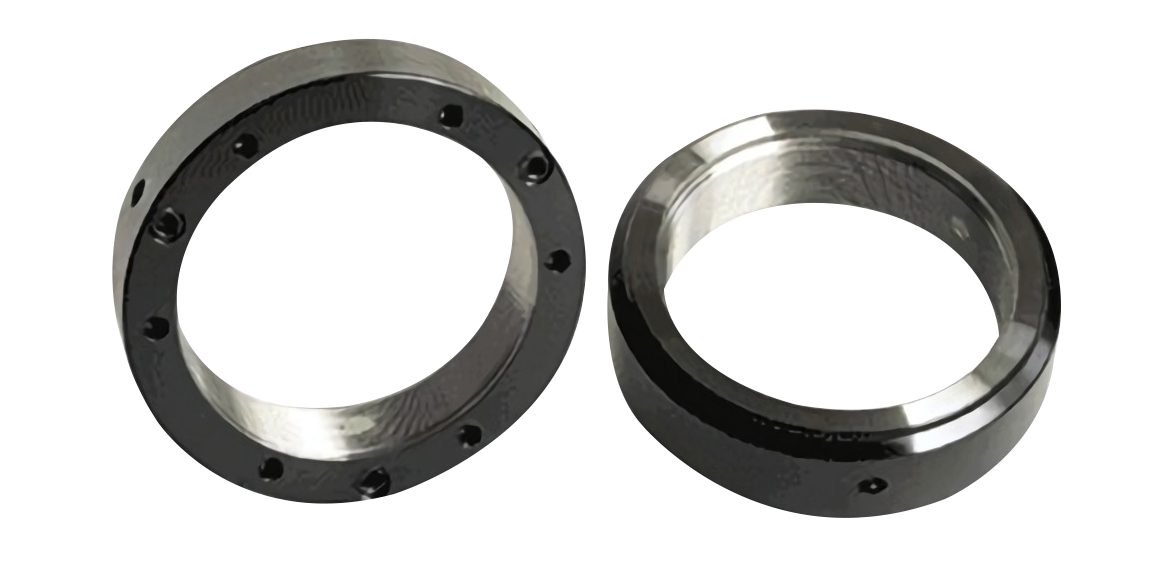

■ Features

- Material : DIN C45, JIS S45C, KS SM45C

- Hardness : HRC 20 ~ 25

- Nut Grade : Precision class

- Squarness of Nut Face : ⊥0.002~0.015

■ Advantages

1. Thanks to enhanced flatness and roughness of reference plane by lapping work, YHB thpe fits

in shaft build-up which requires hight fixing dedree.

2. Three locking pins located in equal intervals enable the nut to be assembled with the

shaft exactly at appropriate angle and adjust the deviation properly.

3, Keeps a good balance thanks to the equal interval fluting of lock pin and hook spanner.

Specification

| PART NO | THREAD & PITCH | Dimension | Axial Load (KN) |

Set Screw (Nm) |

Weight (g) |

|||||||||

| d1 | b2 | d3 | d4 | B | g | t | m | m | m | |||||

| HB 05 | M 25 × 1.5 | 33.5 | 42 | 35 | 26 | 20 | 32.5 | 11 | 4.3 | 5 | M6 | 130 | 8 | 123 |

| HB 06 | M 30 × 1.5 | 39 | 48 | 40 | 32 | 20 | 40.5 | 11 | 4.3 | 5 | M6 | 160 | 8 | 152 |

| HB 07 | M 35 × 1.5 | 44 | 53 | 47 | 38 | 20 | 45.5 | 11 | 4.3 | 5 | M6 | 190 | 8 | 174 |

| HB 08 | M 40 × 1.5 | 49 | 58 | 52 | 42 | 22 | 50.5 | 12 | 4.3 | 5 | M6 | 210 | 8 | 220 |

| HB 09 | M 45 × 1.5 | 56.5 | 68 | 58 | 48 | 22 | 58 | 12 | 4.3 | 5 | M6 | 240 | 8 | 313 |

| HB 10 | M 50 × 1.5 | 60 | 70 | 63 | 52 | 24 | 61.5 | 12 | 4.3 | 5 | M6 | 300 | 8 | 331 |

| HB 11 | M 55 × 1.5 | 65 | 75 | 70 | 58 | 24 | 66.5 | 13 | 4.3 | 5 | M6 | 340 | 8 | 362 |

| HB 12 | M 60 × 1.5 | 72 | 84 | 75 | 62 | 24 | 74.5 | 13 | 5.3 | 5 | M6 | 380 | 8 | 467 |

| HB 13 | M 65 × 1.5 | 76 | 88 | 80 | 68 | 25 | 78.5 | 13 | 5.3 | 5 | M6 | 460 | 8 | 501 |

| HB 14 | M 70 × 1.5 | 83 | 95 | 86 | 72 | 26 | 85 | 14 | 5.3 | 7.9 | M10 | 490 | 18 | 590 |

| HB 15 | M 75 × 1.5 | 88 | 100 | 91 | 77 | 26 | 88 | 13 | 6.4 | 7.9 | M10 | 520 | 18 | 624 |

| HB 16 | M 80 × 2 | 96 | 110 | 97 | 83 | 30 | 95 | 16 | 6.4 | 7.9 | M10 | 620 | 18 | 930 |

| HB 17 | M 85 × 2 | 100 | 115 | 102 | 88 | 32 | 100 | 17 | 6.4 | 9.6 | M12 | 650 | 35 | 1080 |

| HB 18 | M 90 × 2 | 105 | 120 | 110 | 93 | 32 | 108 | 17 | 6.4 | 9.6 | M12 | 680 | 35 | 1140 |

| HB 19 | M 95 × 2 | 110 | 125 | 114 | 98 | 32 | 113 | 17 | 6.4 | 9.6 | M12 | 710 | 35 | 1200 |

| HB 20 | M 100 × 2 | 115 | 130 | 120 | 103 | 32 | 118 | 17 | 6.4 | 9.6 | M12 | 740 | 35 | 1270 |

| HB 22 | M 110 × 2 | 128 | 140 | 132 | 112 | 32 | 128 | 17 | 6.4 | 9.6 | M12 | 800 | 35 | 1400 |

| HB 24 | M 120 × 2 | 138 | 155 | 142 | 122 | 32 | 140 | 17 | 6.4 | 9.6 | M12 | 860 | 35 | 1760 |

| HB 26 | M 130 × 3 | 148 | 165 | 156 | 132 | 32 | 153 | 17 | 6.4 | 9.6 | M12 | 920 | 35 | 1950 |

| HB 28 | M 140 × 3 | 160 | 180 | 166 | 142 | 32 | 165 | 17 | 6.4 | 9.6 | M12 | 980 | 35 | 2300 |

| HB 30 | M 150 × 3 | 173 | 195 | 180 | 152 | 32 | 175 | 17 | 6.4 | 9.6 | M12 | 1040 | 35 | 2500 |

| HB 32 | M 160 × 3 | 182 | 205 | 190 | 162 | 32 | 185 | 17 | 8.4 | 9.6 | M12 | 1100 | 35 | 3050 |

| HB 34 | M 170 × 3 | 192 | 215 | 205 | 172 | 32 | 195 | 17 | 8.4 | 9.6 | M12 | 1160 | 35 | 3280 |

| HB 36 | M 180 × 3 | 205 | 230 | 215 | 182 | 32 | 210 | 17 | 8.4 | 9.6 | M12 | 1220 | 35 | 3780 |

| HB 38 | M 190 × 3 | 215 | 240 | 225 | 192 | 32 | 224 | 17 | 8.4 | 9.6 | M12 | 1280 | 35 | 4030 |

| HB 40 | M 200 × 3 | 223 | 245 | 237 | 202 | 32 | 229 | 17 | 8.4 | 9.6 | M12 | 1340 | 35 | 4000 |