精密配件

정밀부품

Related link

Contents

Feature

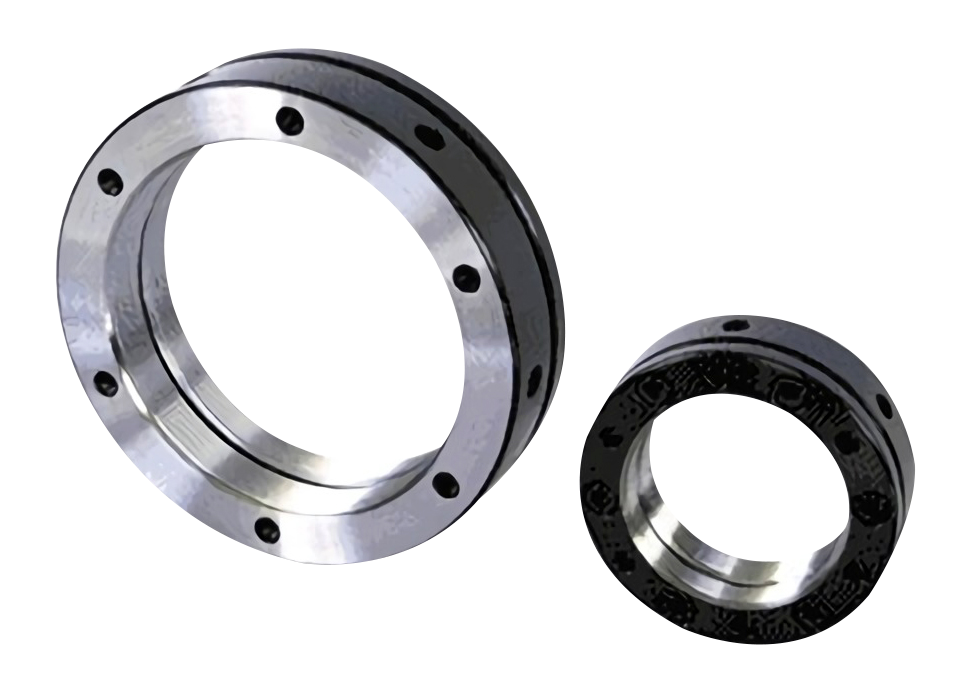

■ Features

- Material : DIN C45, JIS S45C, KS SM45C

- Hardness : HRC 20 ~ 25

- Nut Grade : Precision class

- Squarness of Nut Face : ⊥0.002~0.015

■ Advantages

1. Preload and tension can be adjusted.

2. Tolerative with vibration.(shake, oscillation)

3. Locking washers, slots in the shaft are not needed.

Specification

| PART NO | Dimension | HOLES | TIGHT BOLT | Release Torgue |

Allowble Axal Load |

Weight (g) |

|||||||

| d2 | d3 | d4 | d5 | B | i | Thread & Length |

bolts | torque | |||||

| YAN 16 × 1.5 | 34 | 4 | 24.5 | 4.3 | 18 | 4.5 | 4 | M4 × 12 | 4 | 0.29 | 340 | 22 | 77 |

| YAN 18 × 1.5 | 36 | 4 | 26.5 | 4.3 | 18 | 4.5 | 4 | M4 × 12 | 4 | 0.29 | 370 | 24 | 83 |

| YAN 20 × 1.5 | 40 | 4 | 30.5 | 4.3 | 18 | 4.5 | 4 | M4 × 12 | 4 | 0.29 | 400 | 27 | 105 |

| YAN 22 × 1.5 | 40 | 4 | 30.5 | 4.3 | 18 | 4.5 | 4 | M4 × 12 | 4 | 0.29 | 420 | 30 | 95 |

| YAN 24 × 1.5 | 42 | 4 | 32.5 | 4.3 | 18 | 4.5 | 4 | M4 × 12 | 4 | 0.29 | 440 | 33 | 103 |

| YAN 25× 1.5 | 45 | 5 | 36.5 | 4.3 | 20 | 6 | 4 | M4 × 12 | 4 | 0.29 | 450 | 45 | 139 |

| YAN 28 × 1.5 | 46 | 5 | 38.5 | 4.3 | 20 | 6 | 4 | M4 × 12 | 4 | 0.29 | 480 | 50 | 130 |

| YAN 30 × 1.5 | 48 | 5 | 40.5 | 4.3 | 20 | 6 | 4 | M4 × 12 | 4 | 0.29 | 500 | 55 | 140 |

| YAN 32 × 1.5 | 50 | 5 | 42.5 | 4.3 | 22 | 7 | 4 | M4 × 16 | 4 | 0.29 | 520 | 61 | 164 |

| YAN 35 × 1.5 | 53 | 5 | 45.5 | 4.3 | 22 | 7 | 4 | M4 × 16 | 4 | 0.29 | 550 | 62 | 177 |

| YAN 38 × 1.5 | 58 | 5 | 48.5 | 4.3 | 22 | 7 | 4 | M4 × 16 | 4 | 0.29 | 580 | 72 | 218 |

| YAN 40 × 1.5 | 58 | 5 | 50.5 | 4.3 | 22 | 7 | 4 | M4 × 16 | 4 | 0.29 | 600 | 63 | 198 |

| YAN 42 × 1.5 | 60 | 5 | 52.5 | 4.3 | 22 | 7 | 4 | M4 × 16 | 4 | 0.29 | 620 | 63 | 207 |

| YAN 45 × 1.5 | 68 | 6 | 58 | 4.3 | 22 | 6 | 6 | M4 × 16 | 6 | 0.29 | 1070 | 80 | 290 |

| YAN 48 × 1.5 | 68 | 6 | 59.5 | 4.3 | 25 | 9 | 6 | M4 × 18 | 6 | 0.29 | 1180 | 90 | 298 |

| YAN 50 × 1.5 | 70 | 6 | 61.5 | 4.3 | 25 | 9 | 6 | M4 × 18 | 6 | 0.29 | 1250 | 90 | 310 |

| YAN 52 × 1.5 | 72 | 6 | 63.5 | 4.3 | 25 | 9 | 6 | M4 × 18 | 6 | 0.29 | 1300 | 90 | 320 |

| YAN 55 × 1.5 | 75 | 6 | 66.5 | 4.3 | 25 | 9 | 6 | M4 × 18 | 6 | 0.29 | 1410 | 90 | 336 |

| YAN 58 × 1.5 | 82 | 6 | 72.5 | 5.3 | 26 | 9 | 6 | M5 × 18 | 6 | 0.6 | 2100 | 158 | 456 |

| YAN 60 × 1.5 | 84 | 6 | 74.5 | 5.3 | 26 | 9 | 6 | M5 × 18 | 6 | 0.6 | 2200 | 159 | 471 |

| YAN 62 × 1.5 | 86 | 6 | 76.5 | 5.3 | 28 | 10.5 | 6 | M5 × 20 | 6 | 0.6 | 2310 | 180 | 528 |

| YAN 65 × 1.5 | 88 | 6 | 78.5 | 5.3 | 28 | 10.5 | 6 | M5 × 20 | 6 | 0.6 | 2470 | 170 | 521 |

| YAN 68 × 1.5 | 95 | 8 | 83 | 5.3 | 28 | 9.5 | 6 | M5 × 20 | 6 | 0.6 | 2620 | 215 | 653 |

| YAN 70 × 1.5 | 95 | 8 | 85 | 5.3 | 28 | 9.5 | 6 | M5 × 20 | 6 | 0.6 | 2730 | 200 | 607 |

| YAN 72 × 1.5 | 98 | 8 | 86 | 6.4 | 28 | 8.5 | 6 | M6 × 20 | 6 | 1 | 3640 | 158 | 619 |

| YAN 75 × 1.5 | 100 | 8 | 88 | 6.4 | 28 | 8.5 | 6 | M6 × 20 | 6 | 1 | 3750 | 200 | 620 |

| YAN 80 × 2.0 | 110 | 8 | 95 | 6.4 | 32 | 11 | 6 | M6 × 22 | 6 | 1 | 3900 | 169 | 968 |

| YAN 85 × 2.0 | 115 | 8 | 100 | 6.4 | 32 | 11 | 6 | M6 × 22 | 6 | 1 | 4000 | 167 | 1020 |

| YAN 90 × 2.0 | 120 | 8 | 108 | 6.4 | 32 | 11 | 6 | M6 × 22 | 6 | 1 | 4200 | 255 | 1070 |

| YAN 95 × 2.0 | 125 | 8 | 113 | 6.4 | 32 | 11 | 6 | M6 × 22 | 6 | 1 | 4350 | 262 | 1120 |

| YAN 100 × 2.0 | 130 | 8 | 118 | 6.4 | 32 | 11 | 6 | M6 × 22 | 6 | 1 | 4500 | 268 | 1180 |

| YAN 105 × 2.0 | 135 | 8 | 123 | 6.4 | 32 | 11 | 6 | M6 × 22 | 6 | 1 | 4650 | 270 | 1230 |

| YAN 110 × 2.0 | 140 | 8 | 128 | 6.4 | 32 | 11 | 6 | M6 × 22 | 6 | 1 | 4800 | 280 | 1280 |

| YAN 115 × 2.0 | 145 | 8 | 133 | 6.4 | 36 | 13 | 6 | M6 × 25 | 6 | 1 | 4950 | 325 | 1540 |

| YAN 120 × 2.0 | 155 | 8 | 140 | 6.4 | 36 | 13 | 6 | M6 × 25 | 6 | 1 | 5100 | 403 | 1910 |

| YAN 125 × 2.0 | 160 | 8 | 148 | 6.4 | 36 | 13 | 6 | M6 × 25 | 6 | 1 | 5250 | 410 | 1980 |

| YAN 130 × 3.0 | 165 | 8 | 153 | 6.4 | 36 | 13 | 6 | M6 × 25 | 6 | 1 | 5450 | 400 | 2980 |

| YAN 140 × 3.0 | 180 | 10 | 165 | 6.4 | 36 | 12 | 8 | M6 × 25 | 8 | 1 | 5700 | 472 | 2510 |

| YAN 150 × 3.0 | 190 | 10 | 175 | 6.4 | 36 | 12 | 8 | M6 × 25 | 8 | 1 | 6000 | 485 | 2680 |

| YAN 160 × 3.0 | 205 | 10 | 185 | 8.4 | 40 | 14 | 8 | M8 × 30 | 8 | 2.5 | 6300 | 550 | 3630 |

| YAN 170 × 3.0 | 215 | 10 | 195 | 8.4 | 40 | 14 | 8 | M8 × 30 | 8 | 2.5 | 6650 | 555 | 3840 |

| YAN 180 × 3.0 | 230 | 10 | 210 | 8.4 | 40 | 14 | 8 | M8 × 30 | 8 | 2.5 | 7000 | 640 | 4570 |

| YAN 190 × 3.0 | 240 | 10 | 224 | 8.4 | 40 | 14 | 8 | M8 × 30 | 8 | 2.5 | 7300 | 650 | 4790 |

| YAN 200 × 3.0 | 245 | 10 | 229 | 8.4 | 40 | 14 | 8 | M8 × 30 | 8 | 2.5 | 7600 | 570 | 4470 |